HELLER solutions at KSB

50% shorter machining time to produce fittings

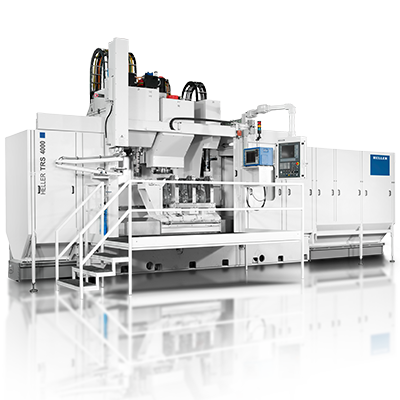

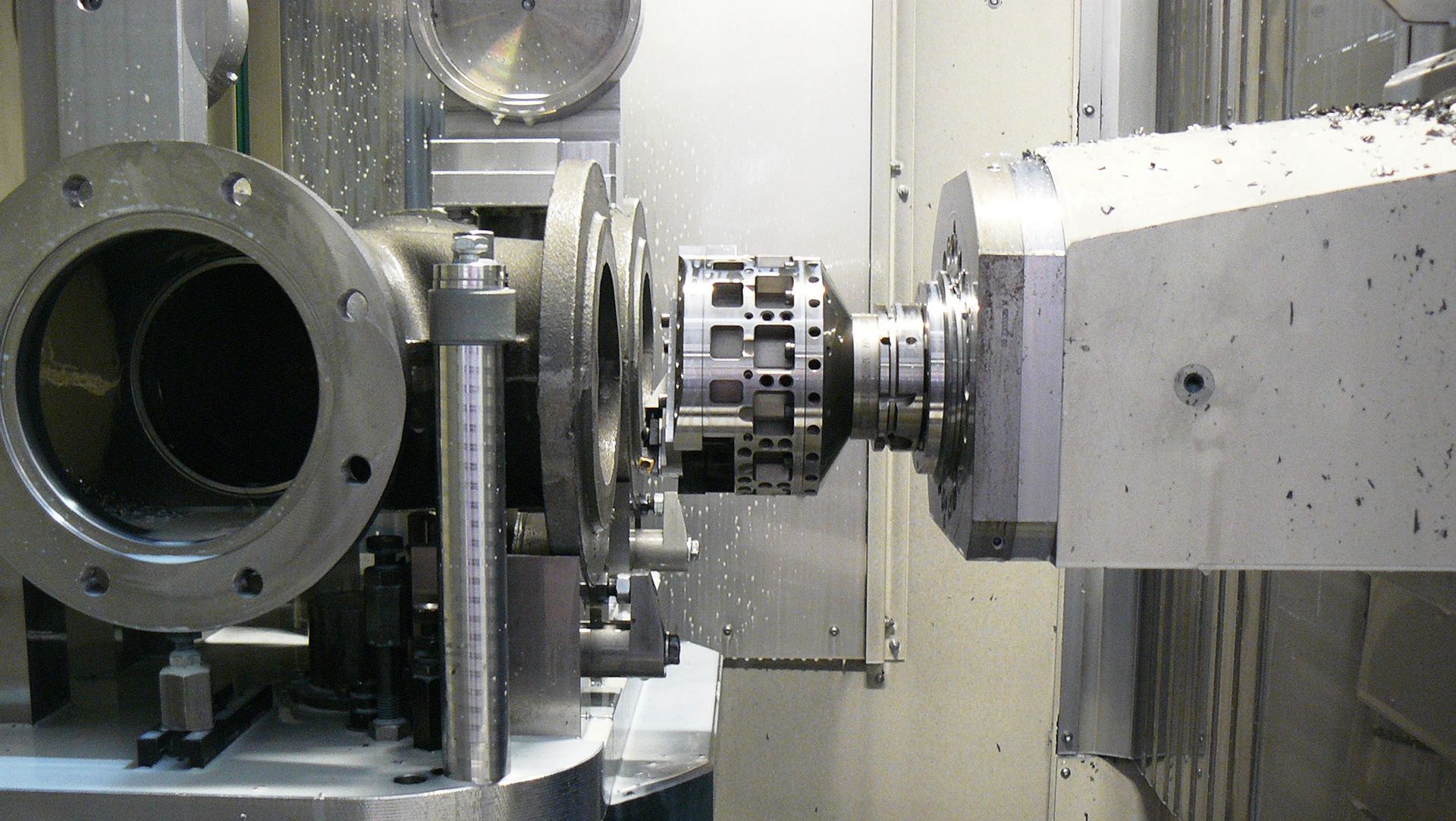

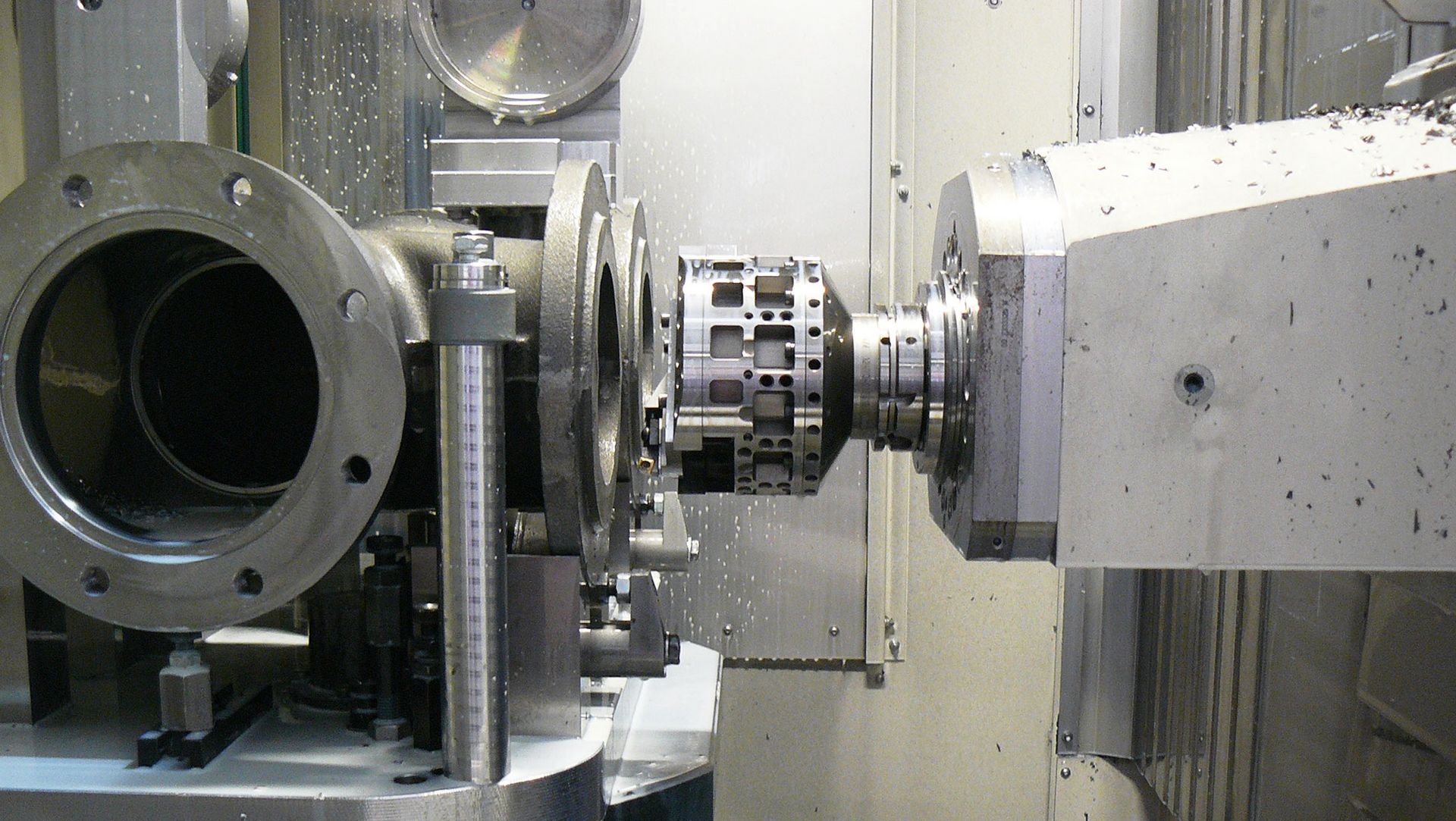

The goal of KSB AG was to achieve a reduction in machining times. Considering the annual output of approx. 40,000 valve bodies, it required a highly productive and flexible concept to achieve this goal. The exchangeable out-facing head on the HELLER machining center model MCH 280 provided the solution. In addition to savings in machining time, it also allowed to achieve a significant reduction in set-up times.

Task

- drastically reduced working time alongside higher process reliability for fitting production

- universal machining center that offers sufficient stability for machining grey cast iron and ferrous metal castings

Project scope & solution

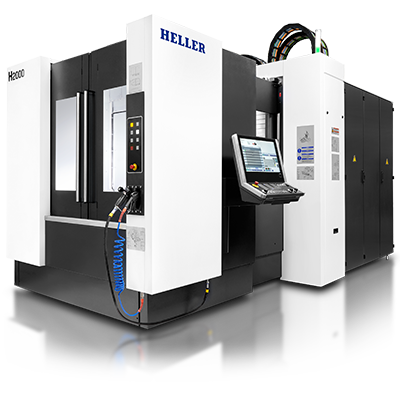

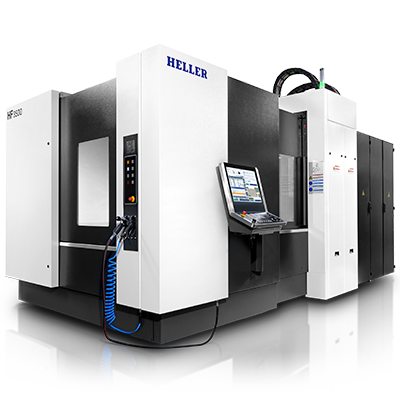

- the MCH 280 from HELLER with programmable U-axis and interchangeable facing heads

- integrated facing slide attachment with direct drive in the machine

- gear unit upgrade to 60 kW, required in particular for rolling

Result

- The MCH 280 is able to machine sealing flanges with just one cutting edge, which saves an enormous amount of time.

- The MCH 280 makes easy work of machining turning grooves, thanks to the freely programmable feed and facing slide attachment.

- facing slide for precise definition of the machining point on the cutting edge

- no collision contour, as the facing slide is coupled through the spindle center

- time required for the machining process reduced by 50% and faster setting, since one machine now handles all the tasks that previously required two machines

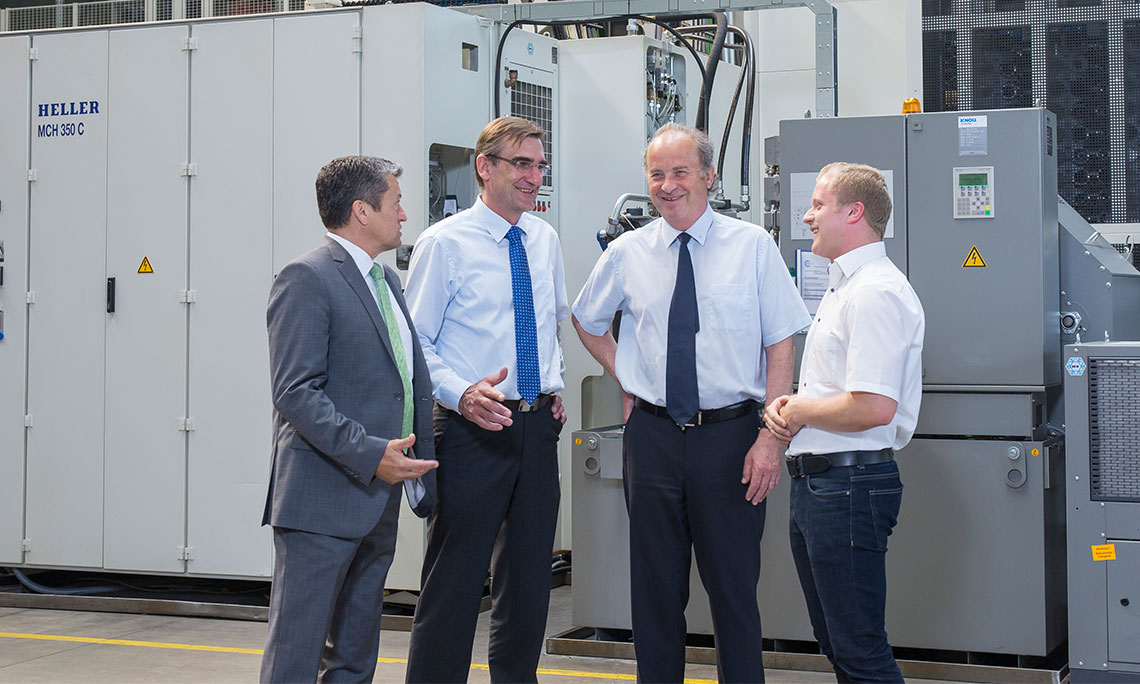

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!