HELLER solutions at CastAlum

Turnkey solution with optimum price/performance ratio

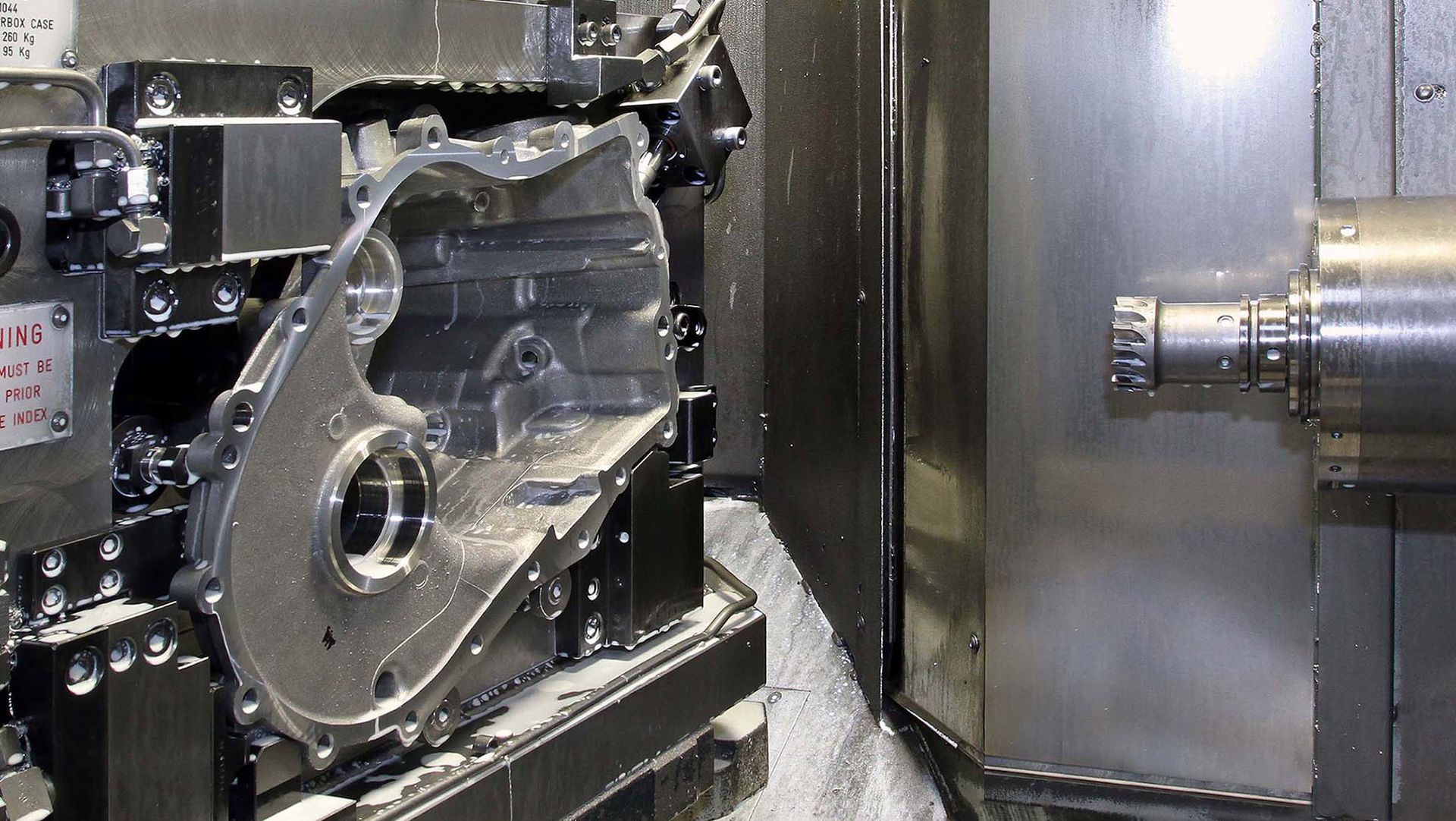

Based in Welshpool, CastAlum is one of the largest aluminum die casting operations in Great Britain. In the search for a turnkey solution with optimum price/performance ratio, HELLER H-series 4-axis machining centers prevailed.

Task

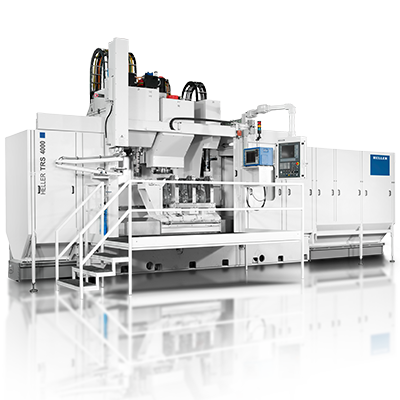

- production facilities have to be able to machine all manner of steering gears and gear housings to achieve a total production volume of 700,000 cast parts/year in two operations, and this hinges on the production facility having the flexibility required

- optimum price/performance ratio

- local, highly reputable customer service

Project scope & solution

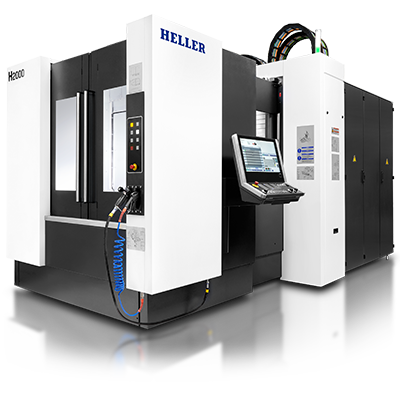

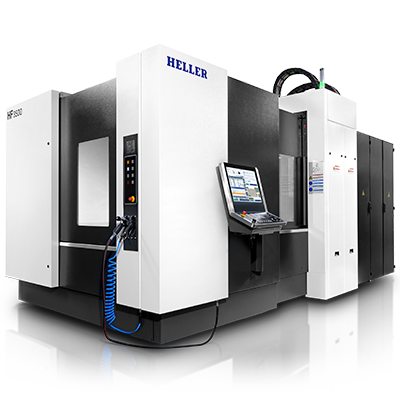

- use of ten H 2000 4-axis machining centres

- cranes located between the individual machine pairs facilitate fast fixture changeover

- the cast parts mounted on the workpiece carriers are transported from the foundry on a long, U-shaped EWAB chain conveyor arranged along the machining centers

Result

- machining centers can be installed in several expansions stages. This allows adjustments to accommodate increasing batch sizes and trouble-free changeover for producing any new workpieces

- HELLER H-series 4-axis machining centers offer outstanding reliability, precision and repeatability

- lean production environment with very low footprint

- average machining center availability of 95 percent achieved by minimizing changeover times

- tolerances respected to within 10 micrometers

- process capability of Cpk 1.67

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!