HELLER solutions at KTM

When it's all about precision, the motorcycle manufacturer relies on HELLER

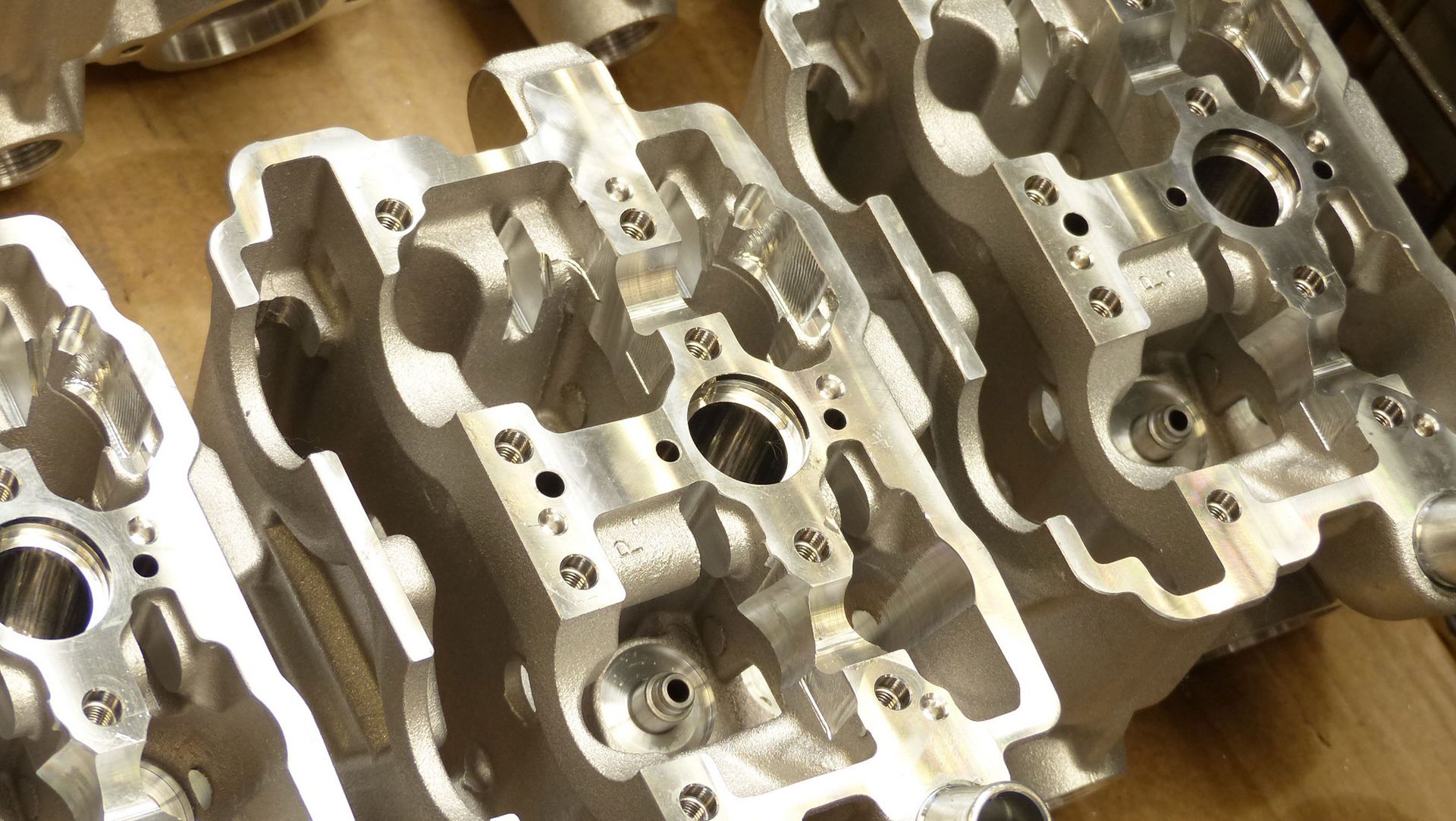

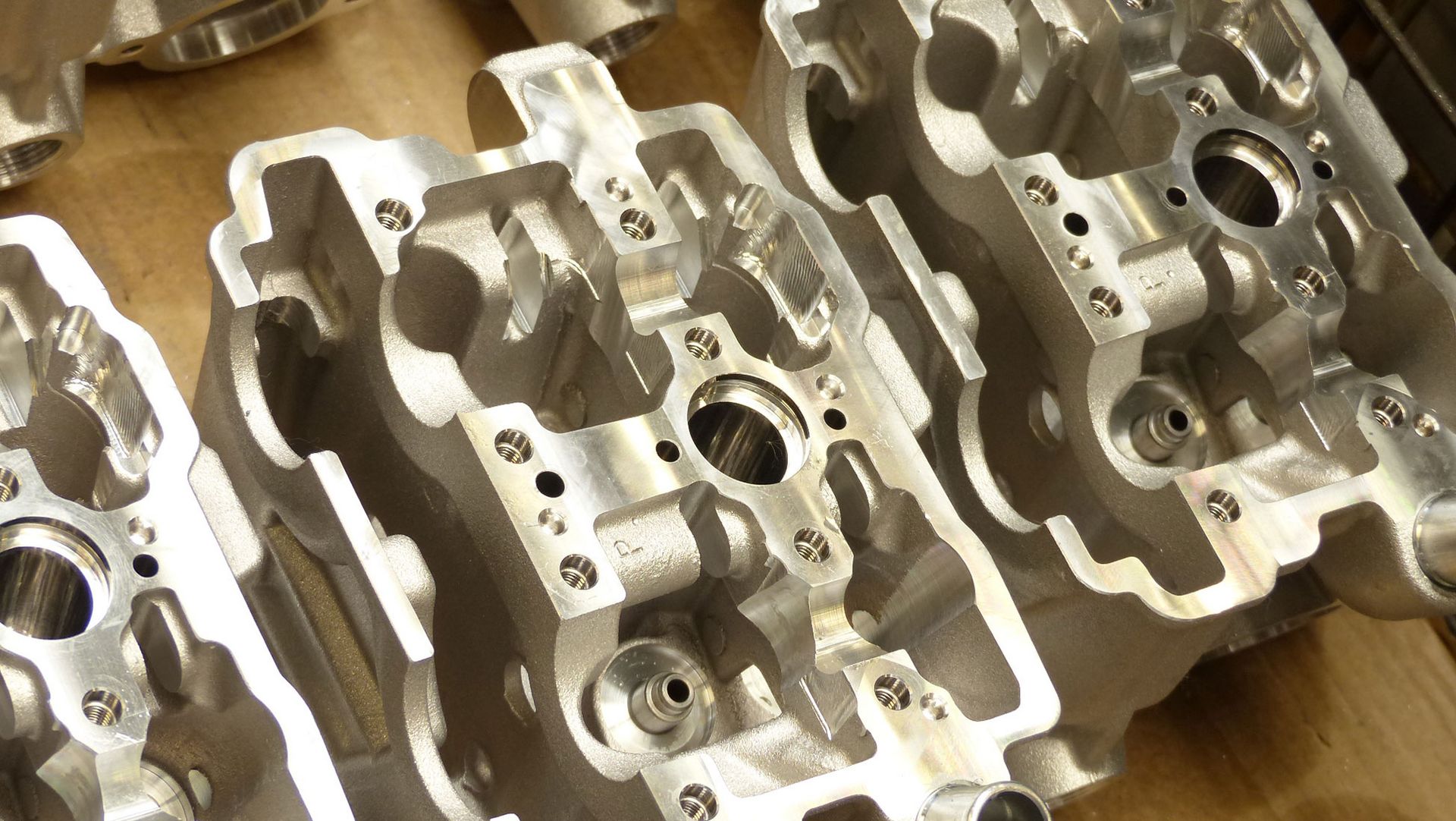

KTM is producing motorcycles at record levels with batch sizes of between 100 and 2000. To machine engine housings and cylinder heads, the company has been relying on HELLER machining centers for 30 years.

Task

- to guarantee precise reproducibility in series production

- flexible, highly dynamic production according to demand and the season

- high degree of vertical integration and part diversity

- batch sizes of between 100 and 2000 units

- three shift operation throughout the year

Project scope & solution

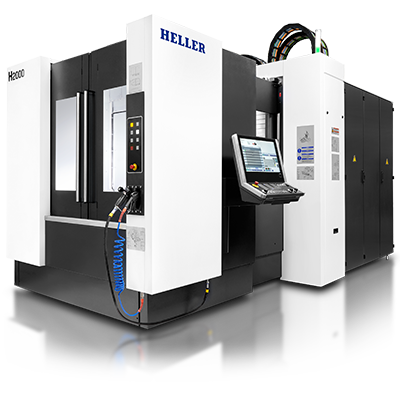

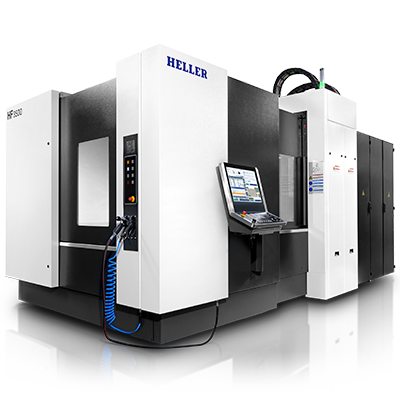

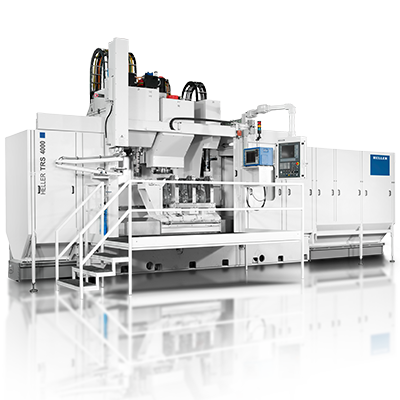

- expansion of 19 completely identical HELLER MC 25 and MCi 25 machines by H-series 4-axis machining centers

- H 4000 with 6-position pallet rotary magazine and 160 tool pockets, as well as a speed package

Result

- tools and clamping systems can be carried over one-to-one on every machine

- machining centers designed for changing batch sizes and a variable range of parts and materials

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!