HELLER solutions at Franz Haas Waffelmaschinen

Reliable & flexible in automated continuous operation

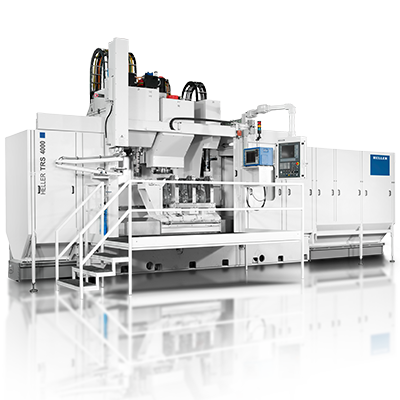

The global leadership of Franz Haas Waffelmaschinen GmbH is based on top quality products and absolute adherence to delivery dates. To be able to manufacture their baking plates flexibly and reliably, the company uses three HELLER H 4000 4-axis machining centers interlinked by the Fastems system.

Task

- high-performance 3D machining

- illustration of baking plates made from spheroidal graphite iron with vastly different contours such as ovals, circulated pyramids, and even complex shapes such as tree trunks.

- parallel to ongoing production, three components from three manufacturers are to be amalgamated to form a functioning overall system in the shortest possible time: the new HELLER machining centers, an upgrade of the existing Fastems system, and also the introduction of a zero point clamping system

Project scope & solution

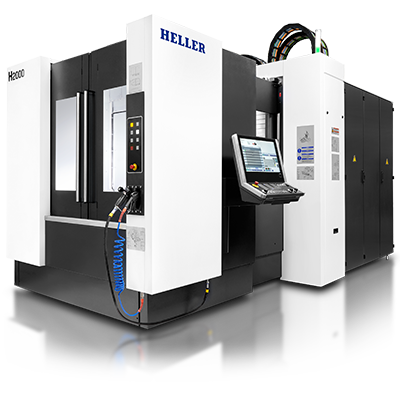

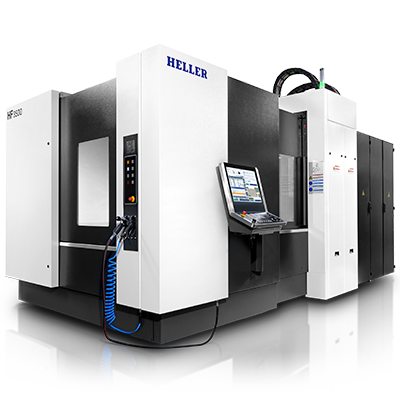

- three HELLER H 4000 4-axis machining centers

- the machines are interlinked by a Fastems manufacturing system

- optional technology software package

- 3D contours are generated by two roughing and two finishing processes

Result

- additional capacities thanks to the high productivity and availability of the three HELLER 4-axis machining centers

- increased manufacturing flexibility through the smooth interaction with the Fastems automation system: large orders with long lead times on the one hand and small batch sizes with short machining times on the other

- throughput times have been sustainably reduced

Contact

Contact

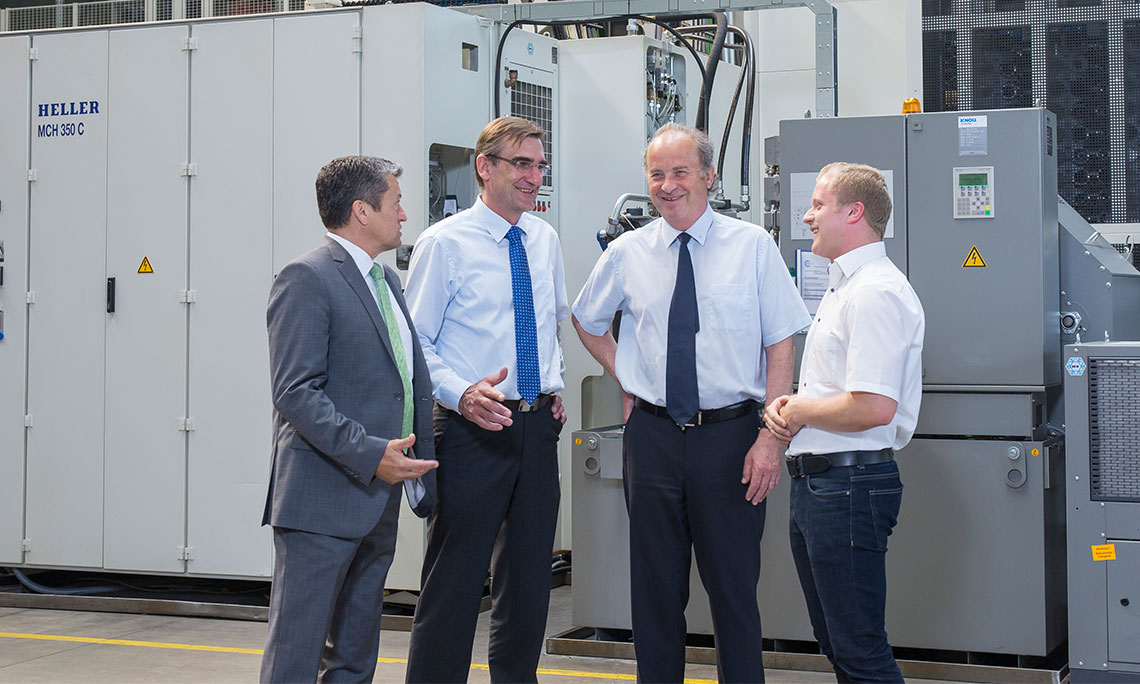

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!