HELLER solutions at RJ

4 and 5 axis machining centers for maximum flexibility

Since the start date of its activity in 1979, the company RJ S.r.l. is mainly engaged in precision mechanical machining applied to industrial vehicles. The progressive growth over the years has led RJ to strategically place itself in a brand new production facility located in San Giorgio Canavese (Turin, Italy), with an area of 110,000 square meters. The RJ group in addition to the headquarter in San Giorgio Canavese has two production plants in Brazil (Joinville) and in the USA (Sterling Heights).

Task

- production of different types of pieces with high volumes

- latest generation machining center for high performance

- high flexibility due to short setting times are very important

- process reliability for high production

Project scope & solution

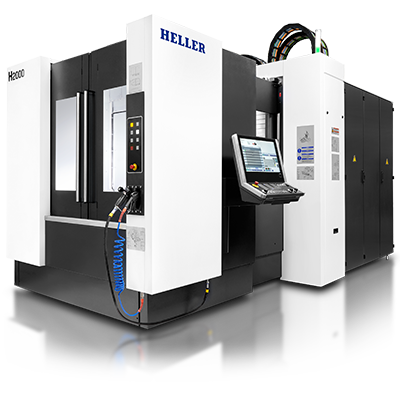

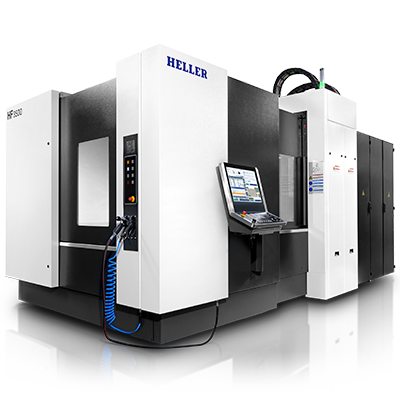

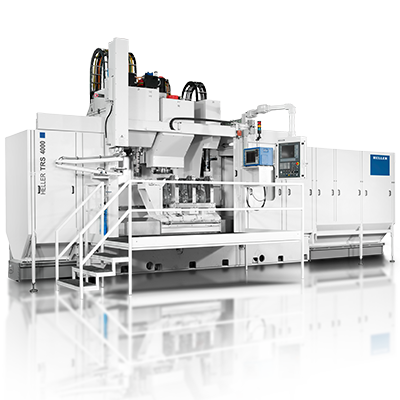

- 35 HELLER machining centers from pallet size 400 x 500 mm to 1.000 x 1.000 mm

- 4 and 5 axis machining centers for maximum flexibility

- spindle units specific for machining of different materials

Result

- possibility to process a wide range of parts with high flexibility

- high machine availability thanks to a close collaboration between the customer's maintenance department and HELLER's technical service

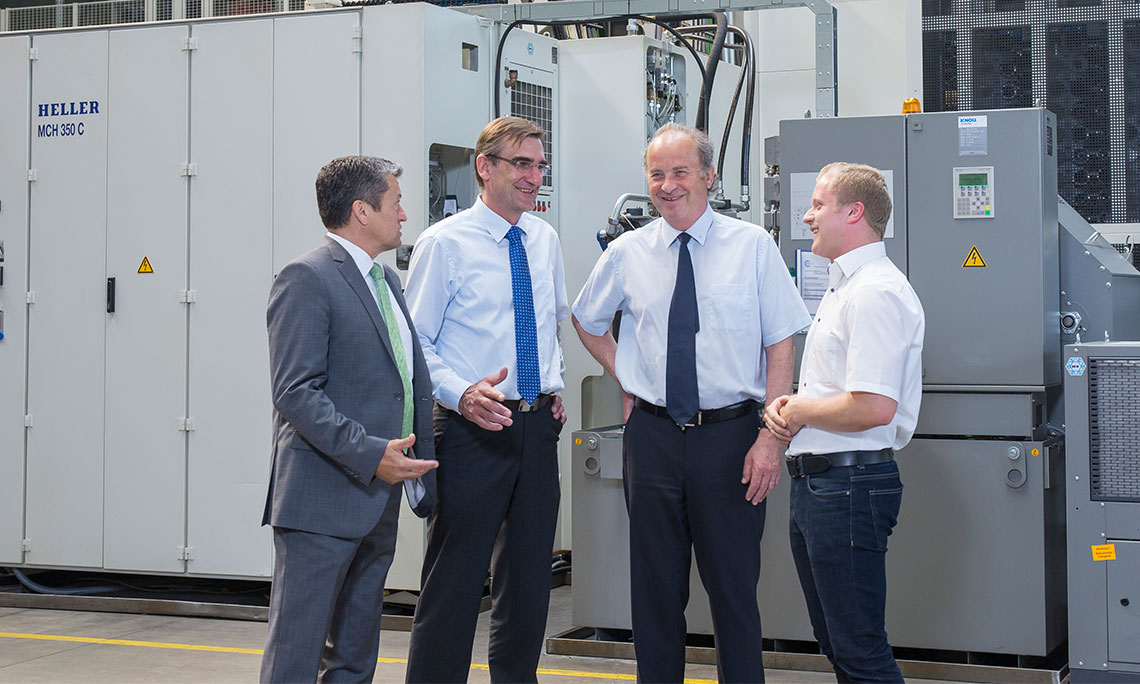

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!