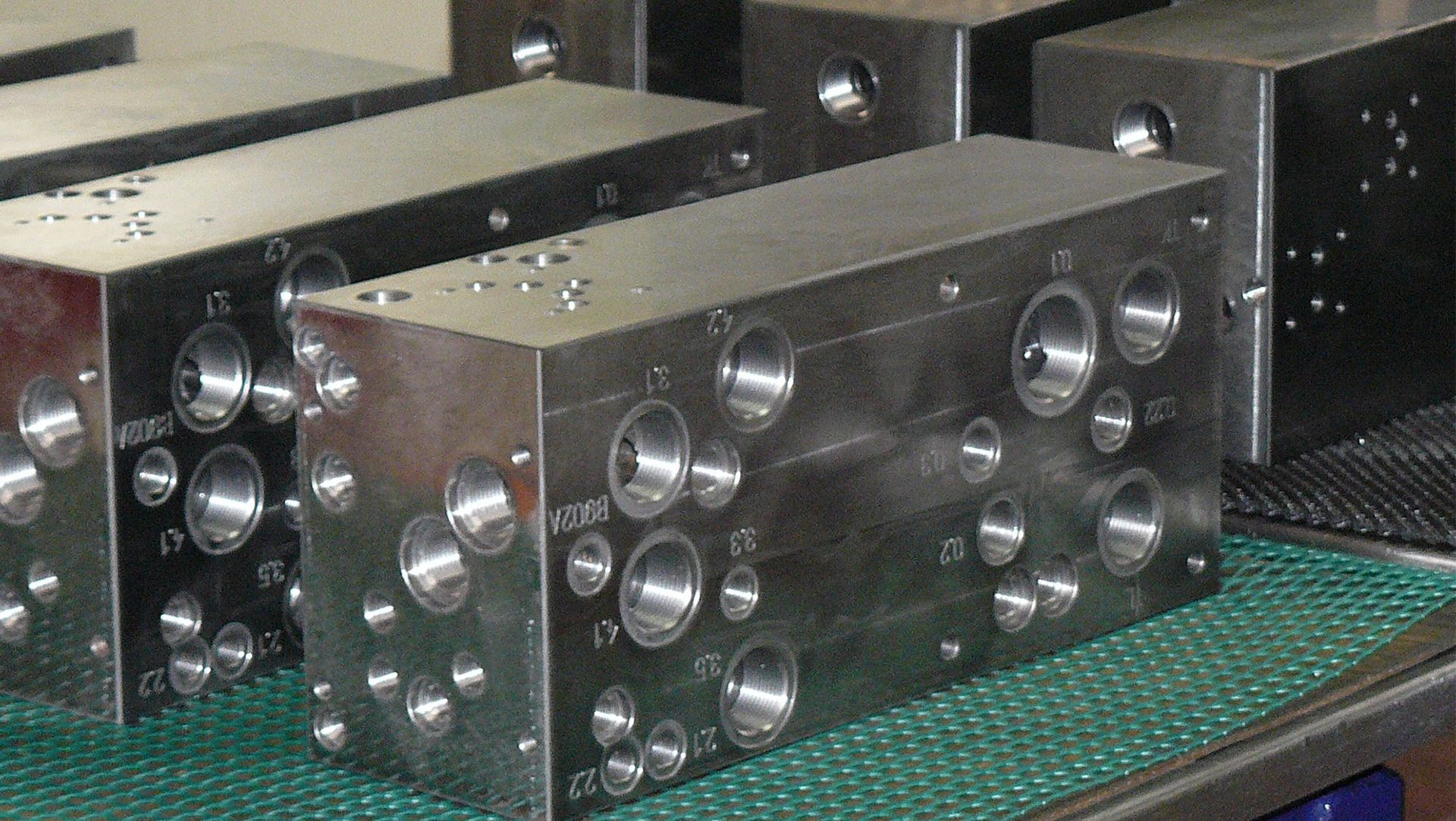

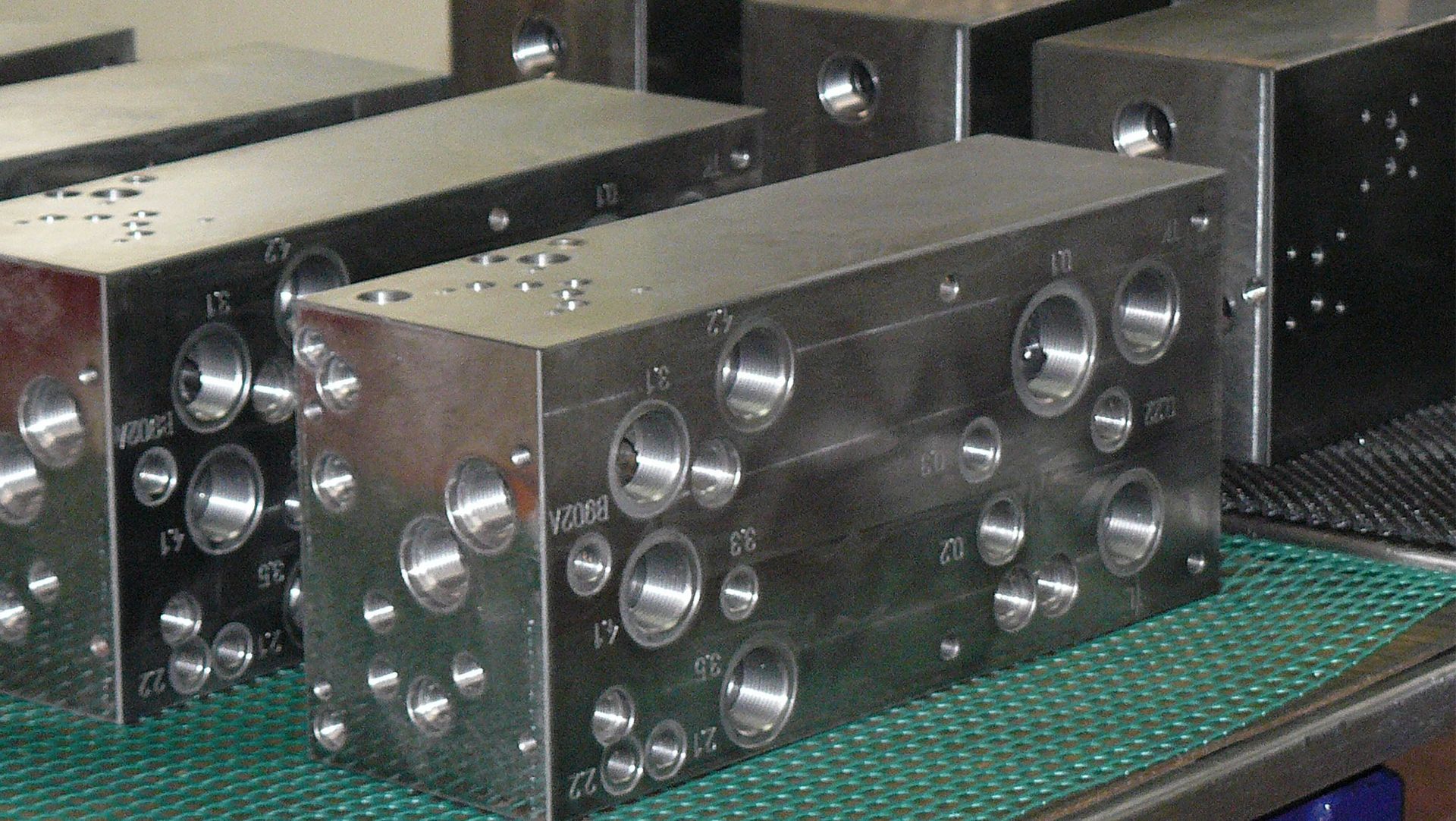

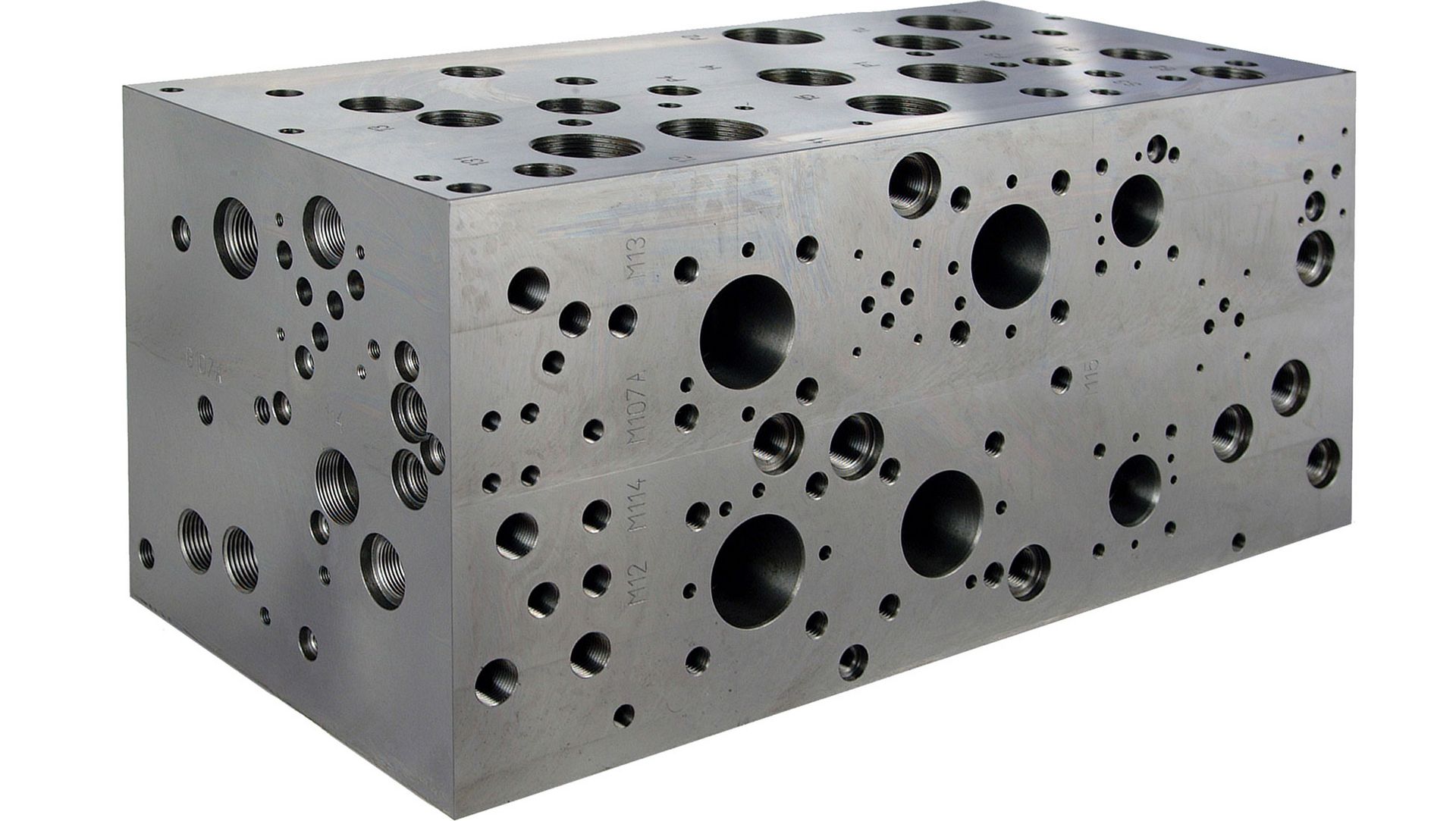

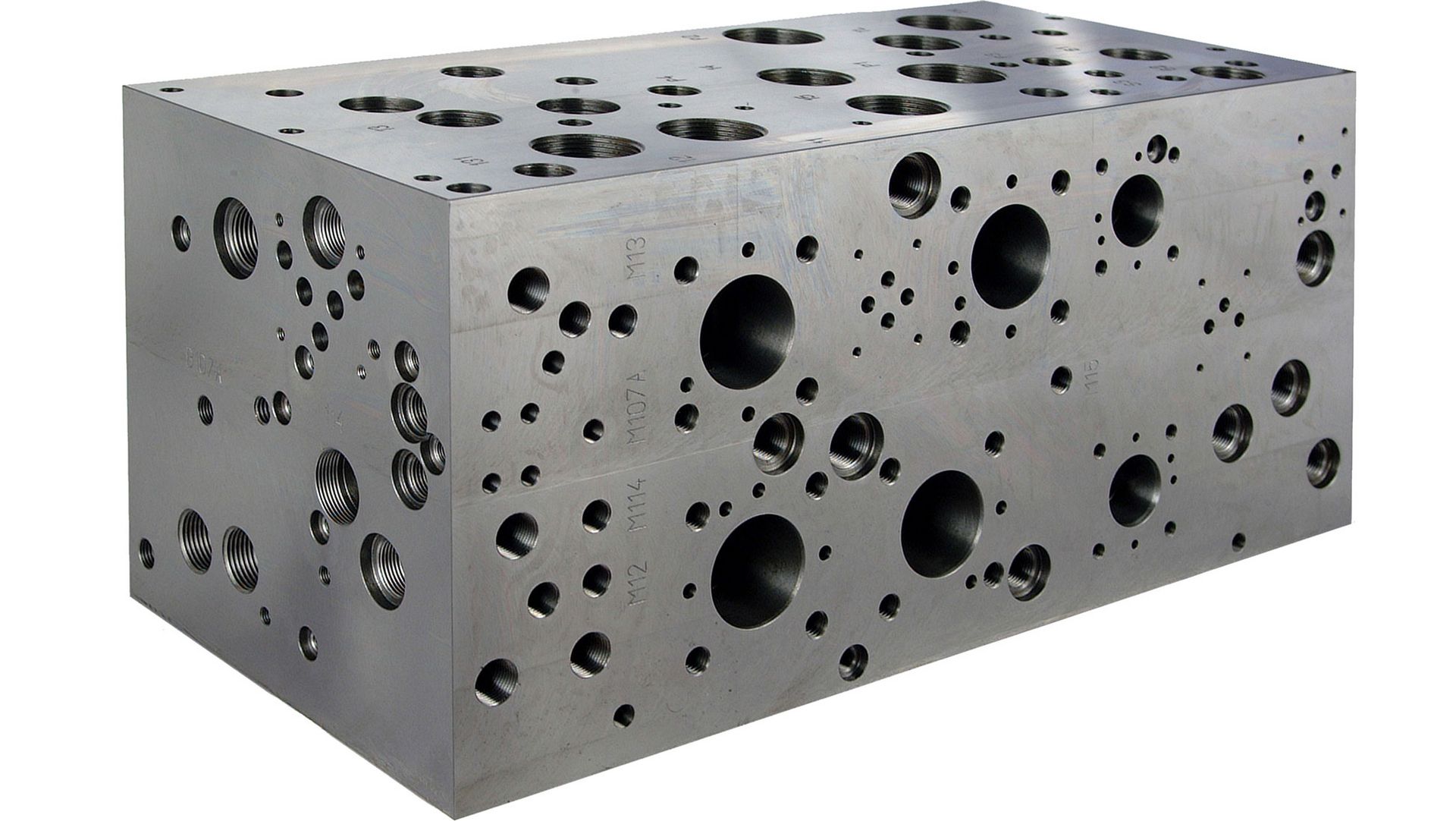

HELLER solutions at Power-Hydraulik

50% energy saving for more productivity alongside a higher degree of process reliability

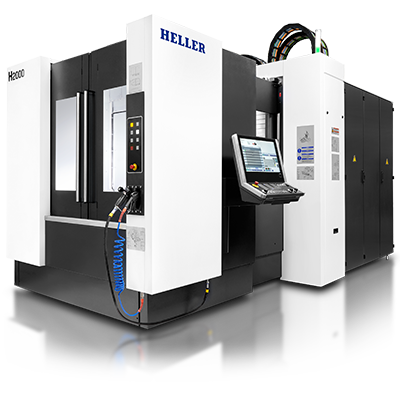

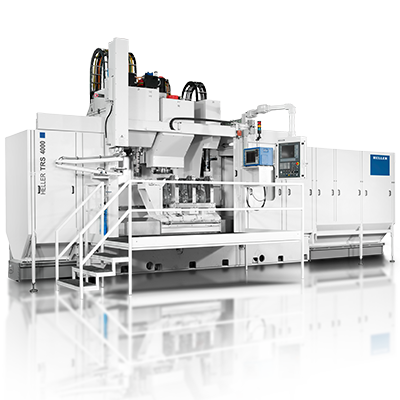

The use of energy filters and modified control technology as well as process-specific modifications to the HELLER machining center model H 2000 and H 4000 helped Power-Hydraulik GmbH to achieve measurable energy savings. At the same time, the machines provide absolute stability and precision. Moreover, pressure monitoring helps to prevent tool breakages and to increase feed rates.

Task

- energy saving when producing control blocks, particularly in the case of coolant-intense boring operations

- energy saving with the high-pressure coolant pump, pressure increase to over 85 bar

- pressure-monitored tool break monitoring

- increased feed speed

Project scope & solution

- HELLER H 2000 4-axis machining center

- pressure increase to over 85 bar

- leak monitoring by sensors

- control system modification for predictive tool break monitoring: starting loop for deep hole drilling, pressure monitoring via frequency inverter

Result

- 50% energy saving alongside a higher degree of process reliability

- less heat input into the coolant, longer coolant pump service life

- leakage reduced by < 5 l/min

- higher degree of process reliability with pressure-based tool break monitoring, applies to any machining operation

- feed speed can be increased thanks to reliable tool break monitoring function

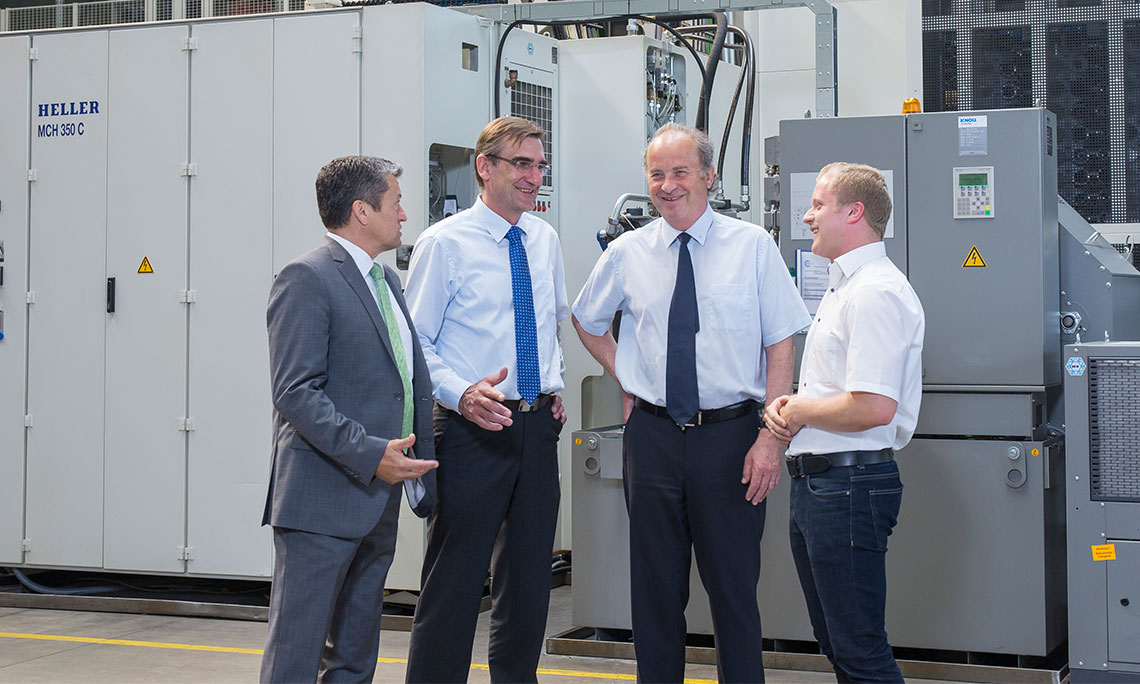

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!