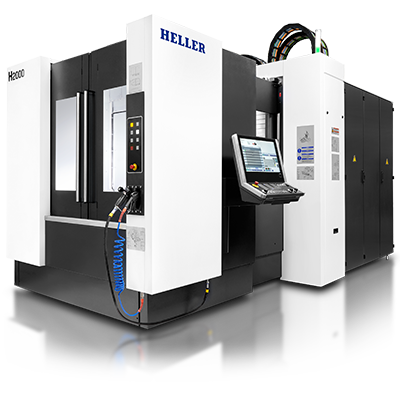

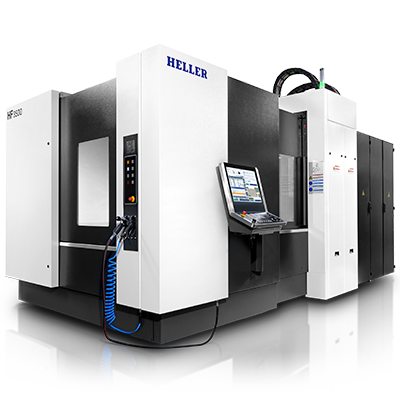

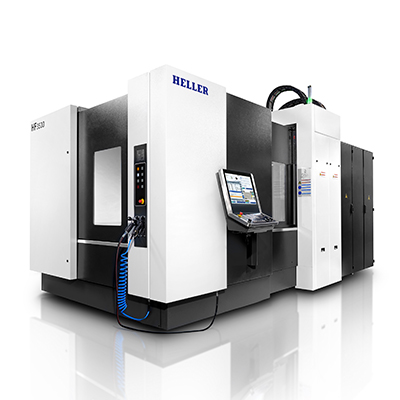

HELLER CNC machine tools

Productivity over the full spectrum

Machine finder

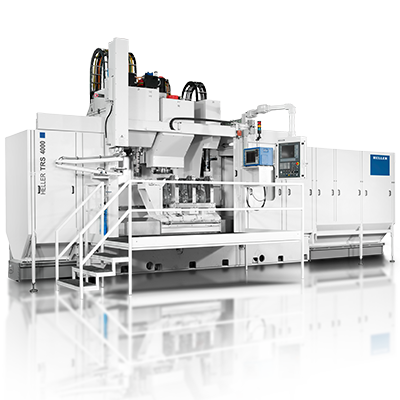

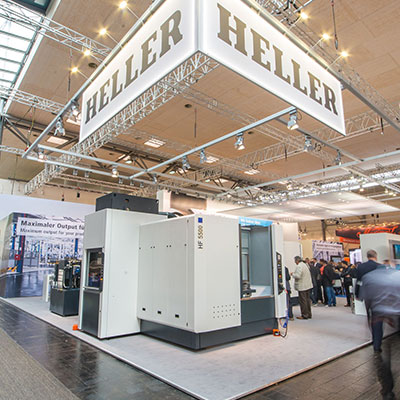

HELLER industry solutions

Tailored for your requirements

Our customers include companies from the automobile industry and their suppliers, from general mechanical engineering, energy technology, fluid technology and many other sectors. A solution that suits your industry and your requirements? HELLER has one. See for yourself.

HELLER Services

Lifetime Partnership

HELLER Services provides you with a comprehensive range of transparent and clearly structured technical services. As a reliable service partner, we support you throughout the entire life cycle of your machine, ensuring its productivity and availability.

Career & Jobs

Shaping the technologies of tomorrow

Are you seeking interesting professional challenges in a pioneering, global machine construction company? Then join the HELLER Group – we will give your career a helping hand!

That's why HELLER

Our company

Our quality pledge

- Made by HELLER:

Deepest vertical integration: HELLER machines produce HELLER machines. - Made to Work:

HELLER machines are designed for stable processes in harsh daily production – 24/7 in a 3-shift operation. - Lifetime Partnership:

HELLER offers comprehensive services over the entire life cycle of a machine. - HELLER Global Footprint:

Our global orientation combined with a strong regional presence ensures customer proximity worldwide.

HELLER the Magazine

Experience it now online!

Delve into the world of HELLER and experience our magazine, presenting you interesting and exciting topics relating to the company, the industry and trends. Now also available online!

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!