HELLER History

From the vice to the highly-flexible manufacturing system

It all began in 1894 when Hermann Heller, just 25 years old, founded a company called "Hermann Heller Handelsgeschäft und Produktion von geschützten Artikeln und Uhrmacherwerkzeug". Today, the HELLER Group develops and produces state-of-the-art CNC machine tools and production systems for machining processes and has 2,600 employees all over the world.

1894

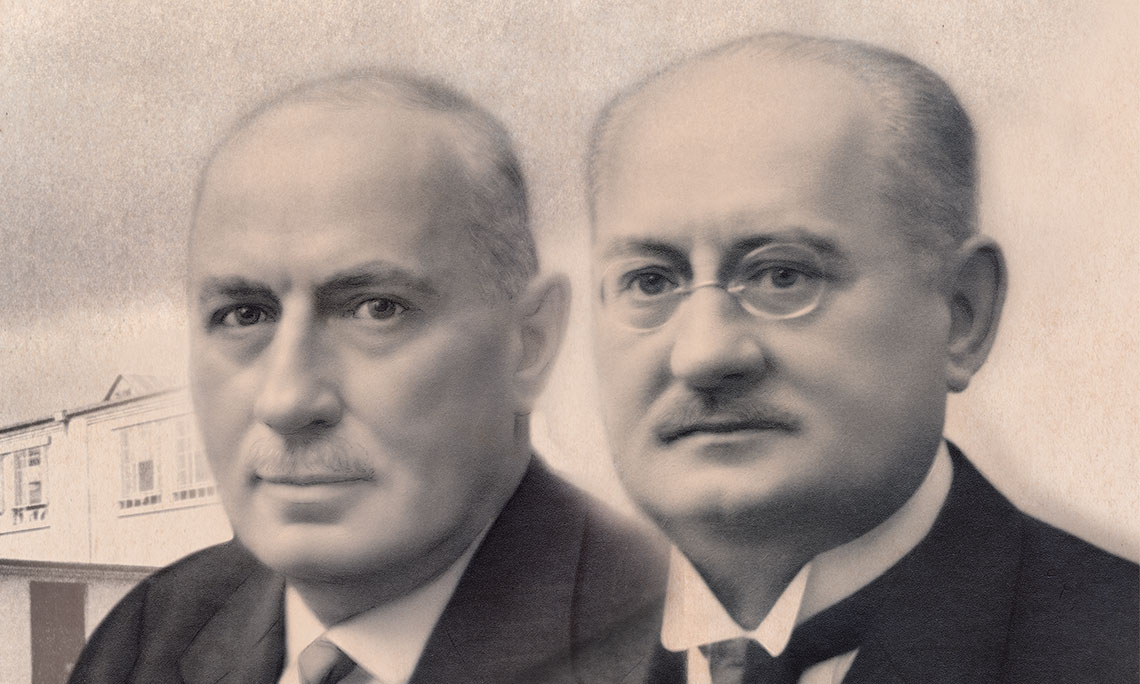

February 7: Hermann Heller (1869-1931) founds a company called "Hermann Heller Handelsgeschäft und Produktion von geschützten Artikeln und Uhrmacherwerkzeugen" in Nürtingen.

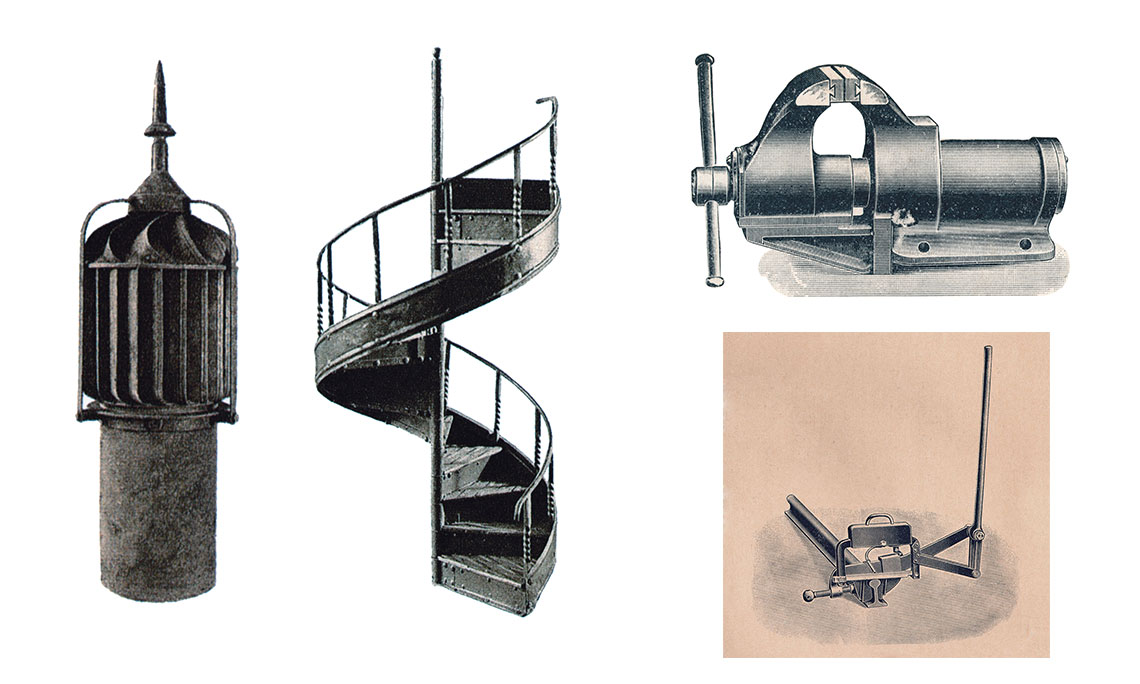

In the beginning, HELLER produces chimney pots, spiral staircases, parallel-jaw vices and other tools.

1898

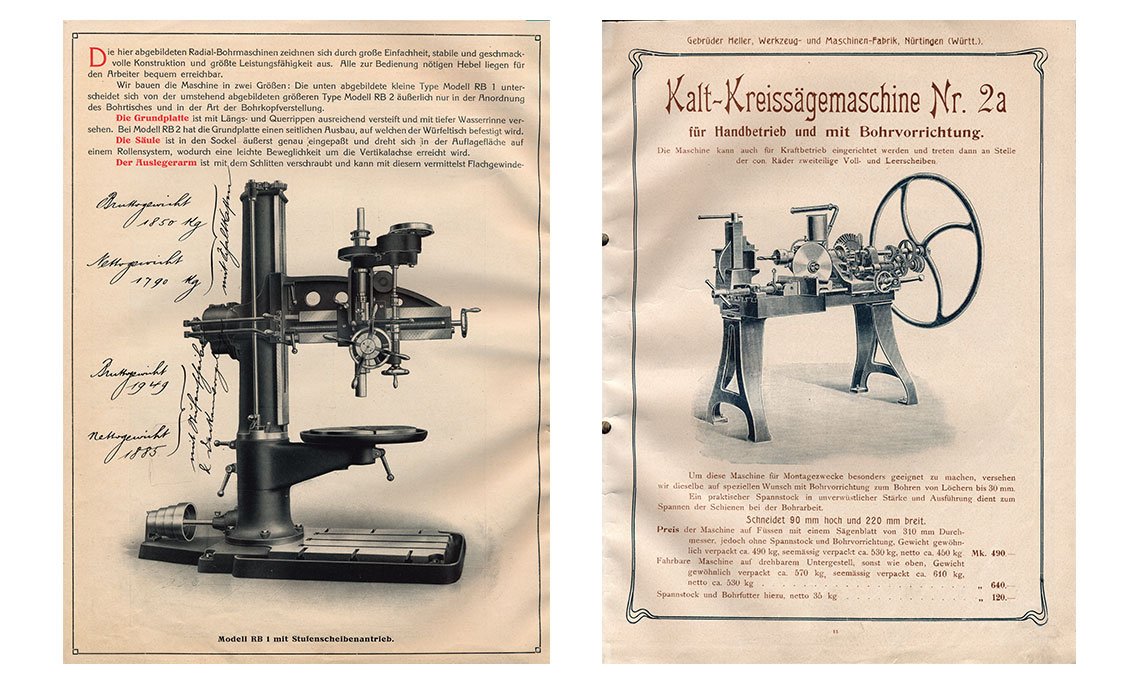

Thread-cutting machines and the first cold circular saws expand the product range.

1899

A portable oscillating saw together with manual sharpener for rail track construction follow next.

1900

January 5: commercial register entry "Gebrüder Heller Werkzeug- und Maschinenfabrik in Nürtingen", the partners are the brothers Ernst Heller (merchant) and Hermann Heller (technician).

1908

At the beginning of the 20th century, HELLER was already successfully selling the RB0, RB1 and RB2 radial drilling machines and the RBS high-performance radial drilling machine. This was a crucial step on the way to becoming a milling machine manufacturer.

1913

The first apprentice workshop is setup in Nürtingen.

1923

HELLER exports to Denmark, delivering abroad for the first time.

1930s

The second generation enters the company.

1935

HELLER developed a special milling machine for the flat machining of a light metal crankcase for the Messerschmitt 109 R aircraft, which reached the world record speed of 755 km/h.

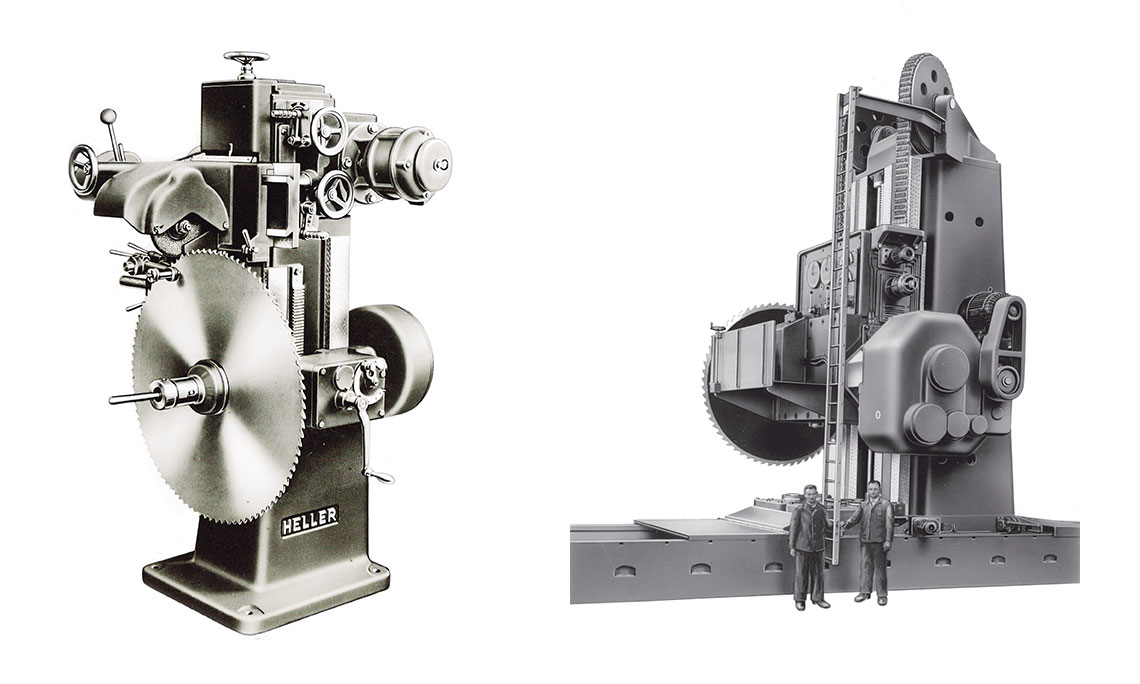

1938

Special design for pillar cold circular saw SKS 3000 weighing 220 t, a 3 meter diameter sawblade and a bed length of 60 meters.

1942

Machine tools from HELLER are equipped with hydraulic control systems – the range now includes crankshaft milling machines.

Modular heavyweight console milling machines are launched on the market.

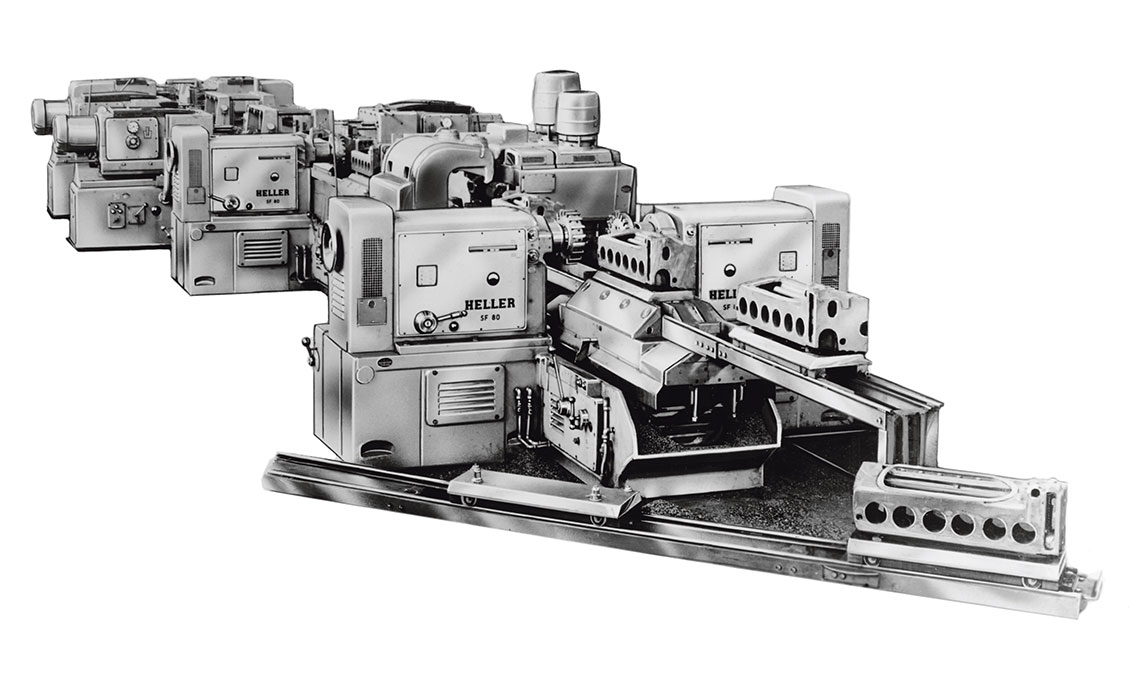

1950s

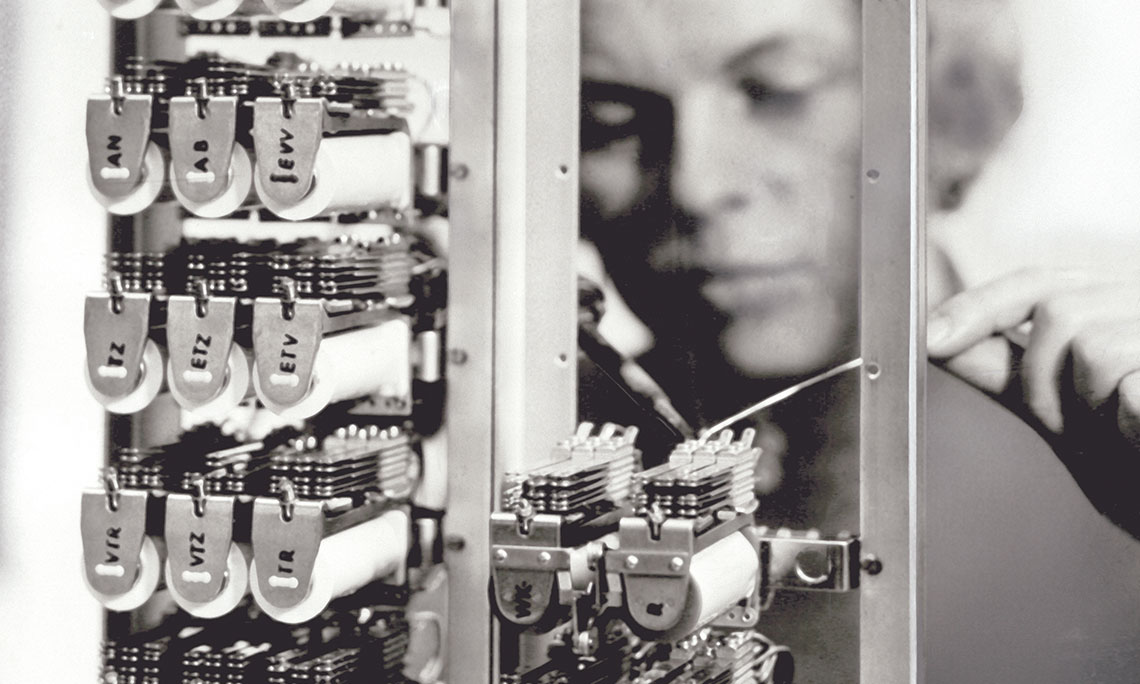

At the time of the economical miracle, HELLER makes more and more custom machines and transfer lines to cover the increasing demand for more production capacity. In addition, HELLER introduces the electro-hydraulic control system (24 volt relay control) for machine tools.

1952

HELLER introduces the FH 140, laying the foundation stone for the company's DNA today. The horizontal production milling machine in a console design, later as a bed construction PF, already has the stability, productivity and reliability gene still typical of HELLER today. This makes it the forerunner of machining centers in the 1960s.

1960s

With Hubert and Berndt Heller, the family's third generation takes over the management of the machine factory.

1962

HELLER develops numerically controlled (NC) milling machines and machining centers with an automatic tool change facility.

1972

Crankshaft milling machines with internal milling for high production follow.

1974

The company expands its network with production workshops in Redditch (England) and Sorocaba (Brazil).

1978

HELLER expands its product range by camshaft milling machines.

1982

With a production site in Chicago, HELLER now has a presence on the US market.

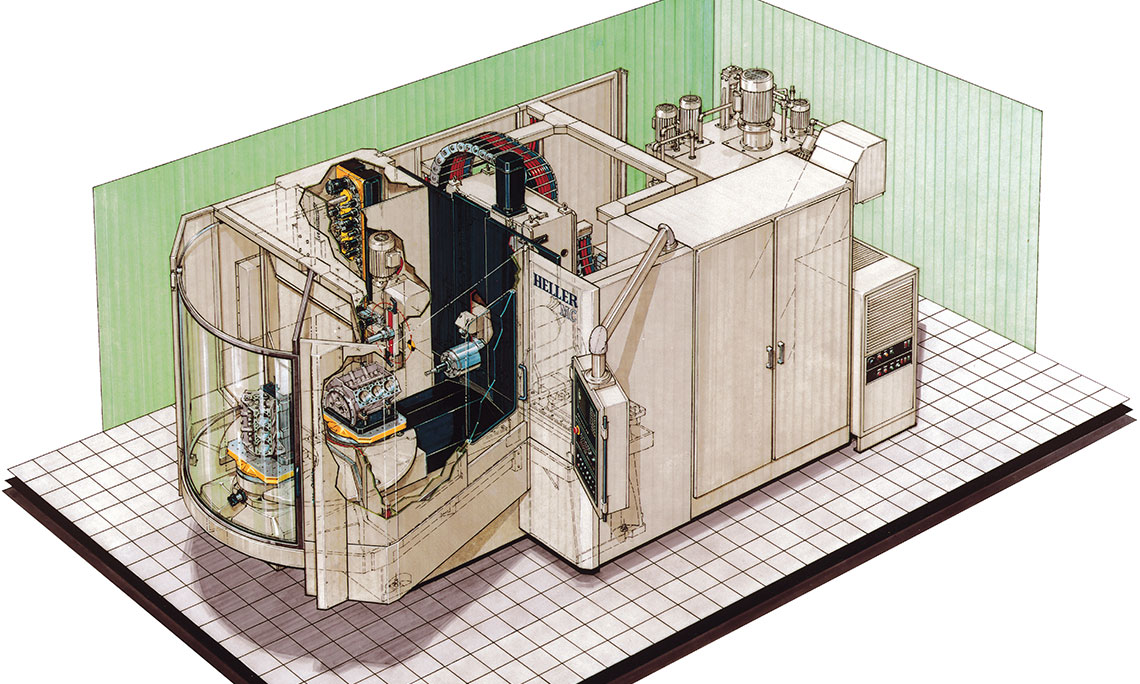

BEA machining centers with the latest CNC technology and proprietary control system (HELLER uniPro NC 80) also go into series production this year.

1985

Opening of the sales and service office in France (Paris).

1990s

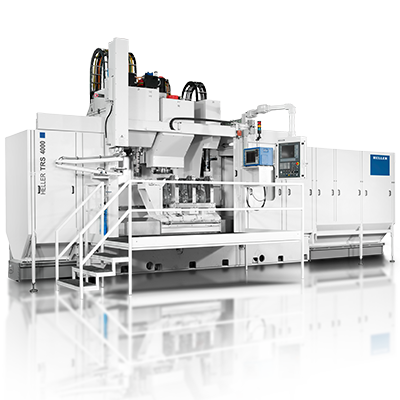

HELLER offers a wide range of flexible and modular machines for numerous applications, providing increased productivity and more efficient manufacturing processes, including machining centers (MCA, MCS, MCP), head changing systems (HCS), crankshaft and camshaft milling machines (RFK, RFN) and turn-broaching centers (DRZ).

1990

Opening of the sales and service office in Italy (Verona).

1991

Founding of the Heller AG as a holding company.

1994

HELLER celebrates its 100th anniversary in a period of economic turbulence.

1995

Opening of the production facilities in the US (Troy/Michigan).

1997

Introduction of the MC machining center range equipped with the new HELLER uniPro CNC 90 control.

2001

Opening of the sales and service office in Mexico (Querétaro).

2002

The HELLER Apprenticeship Initiative (HAI) is introduced by the management and the Youth and Apprentice Representatives (JAV). The aim is to promote social learning in education and social responsibility.

2005

Opening of the sales and service office in Spain (Barcelona).

2006

HELLER acquires GSN Maschinen-Anlagen-Service GmbH. The company from Rottenburg am Neckar specializes in machine rebuilds and overhauls.

Berndt Heller becomes Chairman of the Supervisory Board.

2007

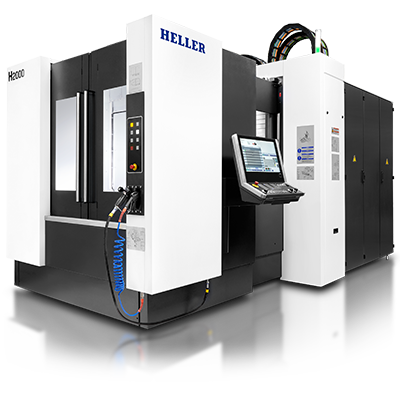

HELLER introduces the new H-series. It comprises flexibly configurable 4-axis horizontal machining centers for a broad range of materials and parts, from single unit manufacture through to large series production.

2008

August Wenzler Maschinenbau GmbH from Spaichingen, a specialist for component production solutions in lightweight construction runs, is acquired.

HELLER invests in the expansion of mechanical production at the Nürtingen site.

2009

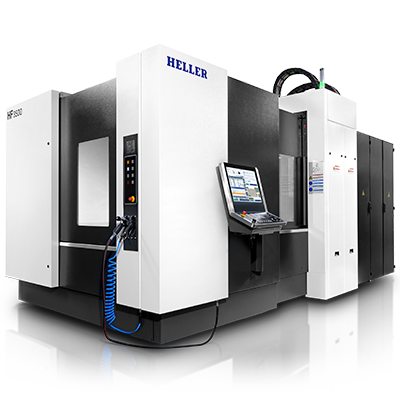

HELLER introduces the new F-series. It comprises 5-axis production machines with and without pallet changer for a broad range of applications in various sectors.

2010

Founding of the "Development New Business & Technologies" department, which sounds out ideas for new business fields as well as the founding of a distribution and service location in Pune, India.

2011

HELLER introduces the new C-series. It comprises 5-axis machining centers for combined milling-turning tasks on one machine (combined processing).

2012

The first CBC modules for the innovative coating of crankcase cylinder bores are delivered.

Start of flow assembly at HELLER in Nürtingen. Others follow in the plants in the USA and Great Britain.

That same year, HELLER receives the largest contract in the company's history.

2013

HELLER opens a production plant in Changzhou (China).

2016

Introduction of the HELLER4Industry concept which, alongside complementary machine functionalities, offers other "on-demand" machine services, as well as a more expansive range of service packages.

HELLER introduces the new HF-series. It comprises 5-axis machining centers, which work highly productively and flexibly and which are easy to operate and maintain.

2017

HELLER4Industry is consistently advanced. HELLER4Use.

The flexible usage model for machining centers is introduced.

2018

HELLER acquires Paatz Viernau GmbH in Thüringen. The company is a specialist in the manufacture of bore heads, multi-spindle heads and complex fixtures.

2019

Inauguration of the new Used Machinery Outlet of STS Maschinendienstleistung GmbH (STS) in Metzingen. In addition to STS, the HELLER Group includes GSN Maschinen-Anlagen-Service GmbH, August Wenzler Maschinenbau GmbH and Paatz Viernau GmbH.

2020

In the middle of the Covid pandemic, the second generation of horizontal 5-axis machining centres from the HF series is presented during a virtual in-house event.

2021

The fourth generation of the proven 4-axis machining centres from the H series is launched. It offers users with a wide range of Industry 4.0 features.

HELLER remains a family-owned company. HELLER Group’s shareholder structure is reorganised: the siblings Nicole Pfleiderer and Marc Heller hold 100 percent of the shares in Heller Holding SE & Co. KGaA.

2023

The inauguration of the extension building at the Changzhou plant is an indication of the importance of the large Chinese market for HELLER.

The new generation of 5-axis machining centres from the F series is presented at EMO.

2024

HELLER celebrates its 130th company anniversary and employs more than 2,600 employees worldwide.

HELLER USA

Milestones

1982

HELLER begins its operations in the United States in Elk Grove Village, IL, primarily as an importer and servicer of its crankshaft milling machines it is then selling to Ford, Deere, Caterpillar and Chevy Bay City plants.

1992

HELLER relocates to Troy, MI.

1993

First major project for HELLER USA with Chrysler.

1995

HELLER builds a new state-of-the-art USA Headquarter and production facility in Troy, MI. In the same year, HELLER USA receives several projects from reputable automotive customers.

1998

HELLER becomes QS certified, which is turned into the current ISO 9001-2000/14001 certifications later on.

2002

After 1999, the building is expanded again to current size with +100,000 sq. ft. for machine assembly.

2006

The success story as a supplier of manufacturing systems for the automotive industry continues, especially with projects for the machining of powertrain components.

2016 & 2017

HELLER USA wins the GM Supplier of the Year Award in two consecutive years.

2018

HELLER USA wins the GM Supplier of the Year Award for the third time in a row. In the same year, a new Sr. Management and new sales team are introduced. HELLER USA is very successful in the oil and gas industry.

2018 – 2019

The renovated lobby and meeting rooms enhance the customer experience and once again expands their sales team.

2019

HELLER introduces a new ExclusiveDistribution Program for the USA.

2020

HELLER USA launches new products (HF Gen2 Series) to the North American market.

2021

HELLER USA launches new products (H Gen4 Series) to the North American market.

Downloads

At a glance, our Download Center offers an extensive range of information materials about our company, our products and services for you to download.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!