Career & Jobs at HELLER

Shaping the technologies of tomorrow

Are you seeking interesting professional challenges in a pioneering, global machine construction company? Then join the HELLER Group – we will give your career a helping hand!

Founded in 1894 in Nürtingen, our company stands for progress, stability and continuity in machine construction to this day. As one of the leading machine tool manufacturers for machining operations, we have a worldwide presence with 2,600 employees.

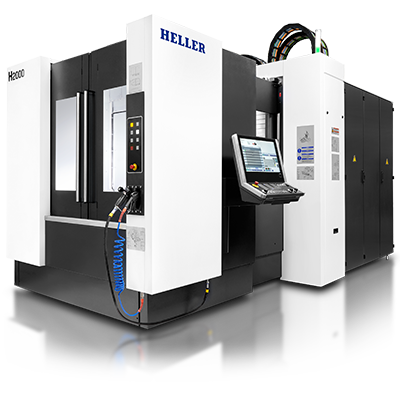

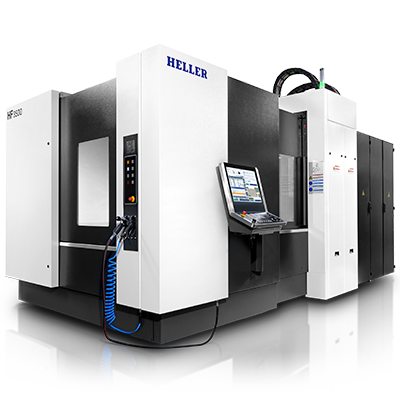

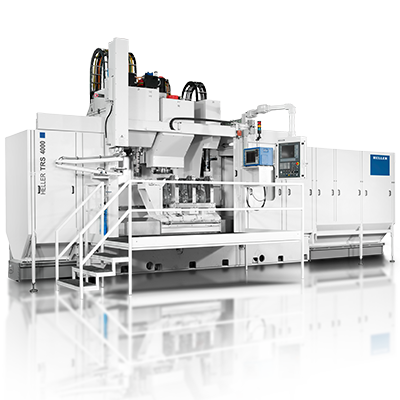

We strive to permanently expand and improve our product range. We focus on new and future technologies that allow us to grow and tap into new areas of business. And for this we always need qualified, or aspiring, specialists and managers.

Vacancies

HELLER USA

Please see our currently open positions here.

We also look forward to receiving your speculative application. If you are interested in possible future opportunities please send your resume to:

Heller Machine Tools L. P.

Human Resources

1225 Equity Dr.

Troy, MI 48084

or via e-mail to hushr@heller.biz.

Click here to go straight to our job portal of HELLER in Germany.

Note: To improve readability, the masculine form is used on our career pages. The information does, of course, apply to all genders.

Values, fields and prospects

The commitment shown by our employees drives our success

We are proud of our employees who commit fully to achieving our company's goals and prosperity. We appreciate this very much. So for us, it's especially important to combine meeting the company's objectives and looking after the interests of the team. And the success of this concept is shown not least by the long service given by our employees, mostly over 20 years and some for as long as 50 years.

We offer our employees modern workplaces and secure jobs with flextime modules that allow working parents also to balance their family life and their profession. In addition, our employees enjoy a good working atmosphere and numerous attractive fringe benefits, including a health management system designed to prevent sickness and maintain our team's efficiency with comprehensive health care.

We also attach great importance to systematic training and development. We want to prepare our employees for current and future challenges and offer a broad range of training opportunities for meeting this objective. A comprehensive talent promotion initiative, regular management training sessions and an international employee exchange program round out our HR development concept.

Secure jobs with prospects

HR development and careers

Work-Life-Balance

Family-friendly working conditions

HELLER health management

Internationality

Out and about with HELLER, all over the world

With our 5 near-to-market production facilities in Germany, USA, England, Brazil, and China, as well as over 30 sales and service branches, we have a presence in the most important markets all over the world. Our international HELLER network creates a sound basis for supporting and supplying our customers in the best possible way. And it's also good for Quality Assurance, helping us keep our "Made by HELLER" promise throughout the world.

Employees on our international team are able to meet other nations, cultures and countries, helping them enhance their language and sociocultural skills. It's not unusual for lifelong, cherished friendships to develop from collaborations over the course of time.

That's why HELLER

Our company

Our quality pledge

- Made by HELLER:

Deepest vertical integration: HELLER machines produce HELLER machines. - Made to Work:

HELLER machines are designed for stable processes in harsh daily production – 24/7 in a 3-shift operation. - Lifetime Partnership:

HELLER offers comprehensive services over the entire life cycle of a machine. - HELLER Global Footprint:

Our global orientation combined with a strong regional presence ensures customer proximity worldwide.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!